DC MCCB Guide: DC500V, DC1000V, DC1500V Breakers Compared - Selection & Protection

2025-08-06

Know the Importance of DC Circuit Protection

With the growth of renewable energy, electric vehicle infrastructure, and a new generation of data centers, the need for reliable DC distribution has increased. As these apps grow in number, circuit protection couldn't be more critical. DC Circuit Breakers, Moulded Case Circuit Breakers (MCCBs). Our DC-specific circuit breakers are a vital cog in the wheel of safety, protecting your electrical systems from overcurrent flow, short circuit, and equipment harm.

There are different demands for the interruption of direct current (DC MCCBs, unlike their AC counterparts, and their choice and utilization could affect the system operation and system safety.

Molded Case Circuit Breaker Fundamentals and Operating Principles

What is an MCCB?

A Molded Case Circuit Breaker (MCCB) is an electrical protection device used to protect equipment from damage caused by fault currents. In DC applications, MCCBs play three different roles as an isolation switch for service purposes, overload protection, and interrupting fault current to protect the system from fault while preserving the safety of personnel.

DC vs AC MCCB Differences

The basic difference between DC and AC MCCBs is their arc-extinction performance. AC crosses zero naturally twice per cycle, making arc extinction easier, and DC is the same as a standstill current, so arc interruption is much more difficult. DC MCCBs feature dedicated arc extinction chambers, improved contacts, and modified spring mechanisms to extinguish DC currents.

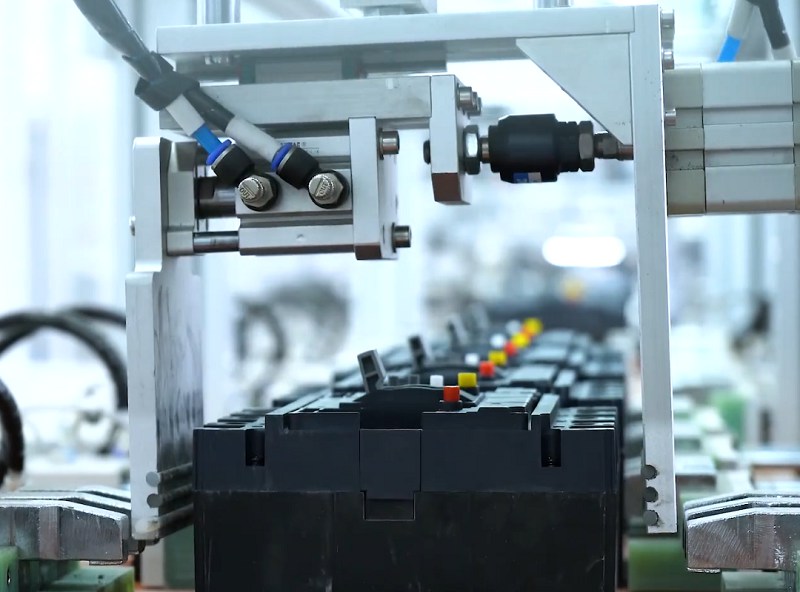

Key Components

Components of a DC MCCB comprises several elements, such as an operating mechanism – spring-loaded to achieve quick contact separation, arc extinction chambers – used for quenching DC arc, thermal and magnetic trip units – for protecting from overload and short-circuit, and contact material – able to withstand DC arcing.

Voltage and Current Ratings

DC500V MCCBs generally have current ratings from 16A to 630A and are suitable for residential solar and small commercial applications. They offer space-saving due to their small footprint design, and their lower voltage for smaller systems maximizes cost effectiveness.

The current range of DC1000V MCCBs is from 32A to 800A, which is in line with commercial solar farms and medium-sized renewable energy applications. The 1000-volt rating matches typical modern photovoltaic system voltages, helping to boost system efficiency.

DC1500V MCCBs are the premium offering, with current ratings up to 800A, and are intended for utility-scale solar fields and large industrial installations that require maximum system voltage utilisation.

Physical Dimensions and Installation

MCCBs withDC500V The most compact in its class, only 105 mm wide for the standard model. DC1000V models typically use a width of 140mm, while DC1500V MCCBs may be 210 mm or wider due to a stronger internal structure and a higher demand for arc extinguishing performance.

3 Application Scenarios and Selection Guide

Solar Photovoltaic Systems

DC500V MCCB for Residential solar applications (500-600V systems). Applicable for systems and Cost-effective protection devices. DC1000V MCCBs are particularly advantageous for commercial solar arrays at 1000V, where string designs can be maximized and system complexity minimized. 15 1500V system Utility-scale solar farms are now using solar systems as high as 1500V with DC1500V MCCBs to reduce energy loss through the conductor and increase power density.

Electric Vehicle Charging Infrastructure

Fast-charged dispensers generally work at 800-1000v, meaning that the DC1000V MCCB is a good candidate to be used. Ultrafast charging systems may need to support high power levels and reliable protection, such as DC1500V MCCBs.

Data Centers and Industrial Automation

More and more new data centers are using DC power distribution to save costs. Depending on system topology, either DC500V or DC1000V MCCBs may adequately protect while facilitating "hot-swap" service.

Selection Criteria

When a DC MCCB is selected, one needs to pay attention to the system voltage, maximum fault current, environmental temperature range, installation space, and upcoming applications for expansion. Make sure the MCB is capable of breaking the highest prospective fault current available by a margin of at least 25% for safety.

Global Market Growth

The DC MCCB market worldwide is booming with renewable and electric vehicle growth. Demand to 2030 is seen rising at compound annual growth rates of over 8%, with Asia-Pacific markets the primary source.

Technological Innovation

Smart MCCB is being developed with IoT connectivity, predictive maintenance, and remote monitoring features. Not only do these breakers show actual status, but they can also forecast failure before it happens.

Major Manufacturers

Major DC MCCB manufacturers such as ABB, Schneider Electric, Eaton, and Chint are still actively developing the technology. Competitive pricing and increased Western standards for quality are both propelling Asian manufacturers to grab market share.

Installation and Maintenance Considerations.

How to Install and Maintain'filters.

Provide sufficient MCCB ventilation, tighten terminals to the appropriate torque, and check the polarity. Provide arc fault indicators where necessary, and make them accessible for maintenance workers.

Common Issues and Troubleshooting

Typical issues include contact wear, thermal ageing, and mechanical wear. Periodic thermography uncovers hotspots in the making while contact resistance tests detect bad connections.

Maintenance Recommendations

Carry out visual checks at least every three months, electrical tests every year, and mechanical operation checks every two years. Substitute components that are visually damaged, deformed, or melted due to severe heat contact.

The best DC circuit protection possible

Choosing a suitable DC MCCB should take into account system voltage, current rating, breaking capacity, and application environment. DC500V MCCBs are ideal for residential and light commercial installations, DC1000V units cover medium commercial-duty systems, and the DC1500V range offers the rugged protection needed for utility-scale projects.

While DC power systems are only in the beginning stages of their evolution, the selection of the correct circuit breaker for these systems is critical to building systems that will operate safely and reliably with good performance. When in doubt, ask electrical protection professionals for the best MCCB selection and installation methods.

The DC Protection of the Future. It is intelligent, connected devices that offer more than just protection—they provide insight into a system that is priceless. The benefits are long-term, as it will help in sustaining the life of the electrical system being installed today and into the smart grid tomorrow.